Applications of KeenAI™

Precision Agriculture

Producers today face the ever-decreasing availability of labor and increasing cost of crop production inputs, including fertilizers, pesticides, and irrigation. Precision agriculture techniques allow site-specific treatments, lowering production costs while minimizing environmental and ecological impacts.

Our KeenAI™ precision agriculture application offers autonomous air and ground multi-modal sensing to identify and classify crop threats, including pests, disease, weeds, and nutrient issues. Many invasive threats can inflict catastrophic damage to crops if not remediated within 48-72 hours. Geo-located threat data, including severity, is delivered to farm operations, which can be resolved through manual or autonomous response teams.

- Quick identification and location of invasive species and disease before extensive crop damage;

- Apply treatments only where needed, reduce production costs and environmental impact;

- Automate labor-intensive operations.

Aircraft

Our Aircraft Inspection, Damage Classification, and Repair Support System delivers an end-to-end capability to autonomously scan aircraft by tail number and detect and classify anomalies. The Model-Based Systems Engineering (MBSE) environment can create, utilize, and update the unique “Digital Twin” (DT) of the aircraft. The system utilizes predictive/prognostic analytics to assess the severity of anomalies and recommended courses of action. Augmented/Virtual Reality (AR/VR) repair guides and instructions for maintainers and over-the-shoulder subject matter experts (SME) reach back if required to support repair operations. System configurations can support Maintenance, Repair, and Overhaul operations and also a self-contained, fly away kit for operation at the edge with cloud reach back as required.

- Autonomous Mission Planning and Execution;

- Muti-modal Sensing;

- Anomaly Detection at the Edge;

- AR/VR Repair Support Tools

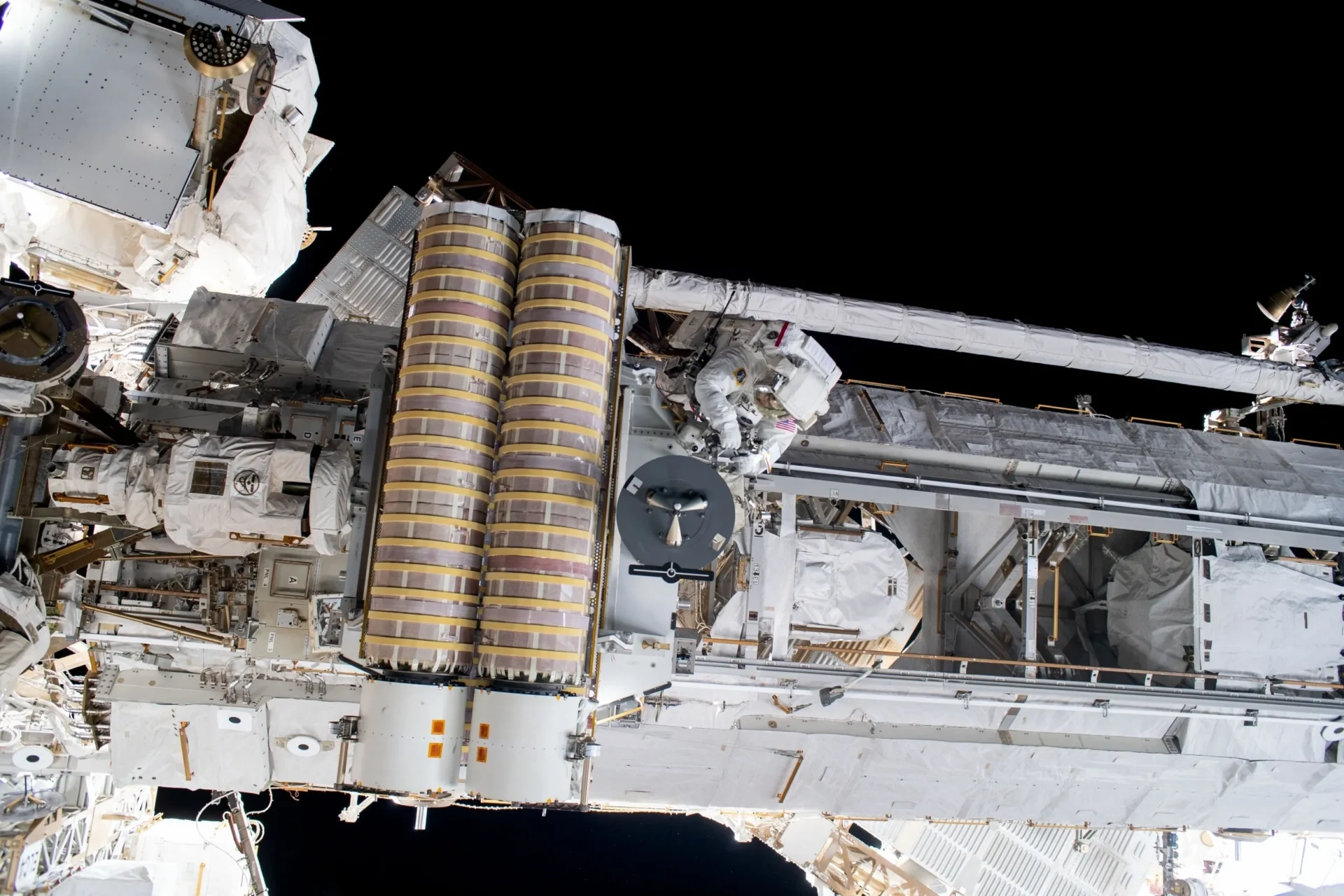

Space

In-Space Servicing, Assembly, and Manufacturing (ISAM) are a rapidly emerging and expanding sector. Inspection and metrology are needed to survey and analyze a spacecraft’s or habitat’s configuration, size, shape, state of repair, or other features of interest. The systems to perform this task include free-flyer inspection, non-destructive evaluation, close (robotic) inspection, and visual or multispectral inspection. The tools utilized for terrestrial critical infrastructure inspection and monitoring are being transformed and hardened for the space environment.

- Condition-based maintenance predictive maintenance;

- Comprehensive facility view including all subsystems;

- Layered 4D time-driven visualization dashboard.

Ships

Our KeenAI™ ship inspection system integrates with cross-domain autonomous systems to deliver a comprehensive interior and exterior inspection capability for ships. The analytics identify, classify, and assess the severity of corrosion, cracks, coating condition, and steel thickness. Using the Model-Based Systems Engineering Environment (MBSE) and ship Digital Twin the degradation of the ship’s condition from the last inspection can be assessed, and condition-based maintenance actions can be prescribed. From hulls to cargo holds and ballast tanks, the cost of inspections can be reduced, personnel safety increased, and the frequency of inspections increased to improve ship efficiency while reducing environmental impacts.

- Improves personnel safety;

- Reduces inspection time and facilities cost;

- Utilizes autonomous cross-domain platforms

Component Maintenance

The autonomous inspection of components can significantly reduce manual inspection time and improve the identification and classification of anomalies for assets under repair and maintenance. The Model-Based Systems Engineering (MBSE) environment can create, utilize, and update the unique “Digital Twin” of each component asset. The system utilizes predictive/prognostic analytics to assess the severity of anomalies and recommended courses of action. A layered 4D time-driven visualization system allows the technician to review the component history to support repair decisions. Augmented/Virtual Reality (AR/VR) repair guides and instructions for maintainers and over-the-shoulder subject matter experts (SME) reach back if required to support repair operations. The system can then be utilized to inspect and sell off the component to return to service after repairs are completed.

- Reduced inspection labor;

- Precision identification and classification of anomalies;

- Layered 4D time-driven visualization dashboard.

Critical Infrastructure

Our Digital Twin Data Acquisition System for Institutional Facility Management delivers an end-to-end capability to autonomously scan interior and exterior facilities across a facility enterprise and utilize subsystem IoT time series data to predict impending system failures to support conditioned-based maintenance to mitigate catastrophic failures. The Model-Based Systems Engineering (MBSE) environment can create, utilize, and update the unique “Digital Twin” of each facility asset. The system supports a wide range of facilities, including buildings, energy production, and transportation infrastructure.

- Condition-based maintenance predictive maintenance;

- Comprehensive facility view including all subsystems;

- Layered 4D time-driven visualization dashboard.

Seaport NxG

Seaport-NxG is the Navy’s electronic platform for acquiring support services in 2 Categories, Engineering and Program Management, with 23 functional area subcategories. The Navy Sea Systems Commands (NAVSEA, NAVAIR, SPAWAR, NAVFAC, and NAVSUP), the Office of Naval Research, Military Sealift Command, and the United States Marine Corps compete for their service requirements amongst 1870 Seaport-NxG IDIQ multiple award contract holders. The Seaport-NxG portal provides a standardized, efficient means of soliciting offers from amongst the diverse population of large and small businesses and their approved team members. All task orders are competitively solicited, awarded and managed using the SeaPort-NxG platform.